PROJECT PRESENTATION FOR SPA CONSIDERATION

"NYÍRPAZONY-KABALÁS 20MVA/23,67MWP” SOLAR PLANT

Company introduction

HT Solar PV Holding Zrt., founded by private individuals in Hungary, decided in 2019 to participate in the day-by-day growing market of renewable energy sector. The sector importance and significant growing is strengthen by responding to the accentuated anti-climate-change fights. The main objective of our project is to encourage the spread of decentralised, environmentally friendly, renewable energy systems in line with the domestic and EU strategy. The immediate aim of the project is to promote the largest possible share of electricity generation on a renewable basis.

The implementation of the project is carried out by HT Solar PV Betulia Kft., the joint subsidiary of HT Solar PV Holding Zrt. and its mentioned two corporate partners.

The electricity produced is delivered to the customer by DSO, the former E.ON Tiszántúli Áramhálózati Zrt., now Opus Titász Zrt., to the Hungarian Electricity Transmission System Operator Zrt. (Hereinafter MAVIR).

From the investor's point of view, the direct goal is to generate a profit from the sale of the produced energy and to create additional renewable power plants. Shortly, in the long term, the main advantages are the predictable operation, relatively fast payback period and sufficient returns.

The project is a photovoltaic power plant on a free-standing, fixed support structure with a capacity of 20MVA/23,67MWp. From the financial point of view of investors, the development was justified by the profit-making potential of renewable energy.

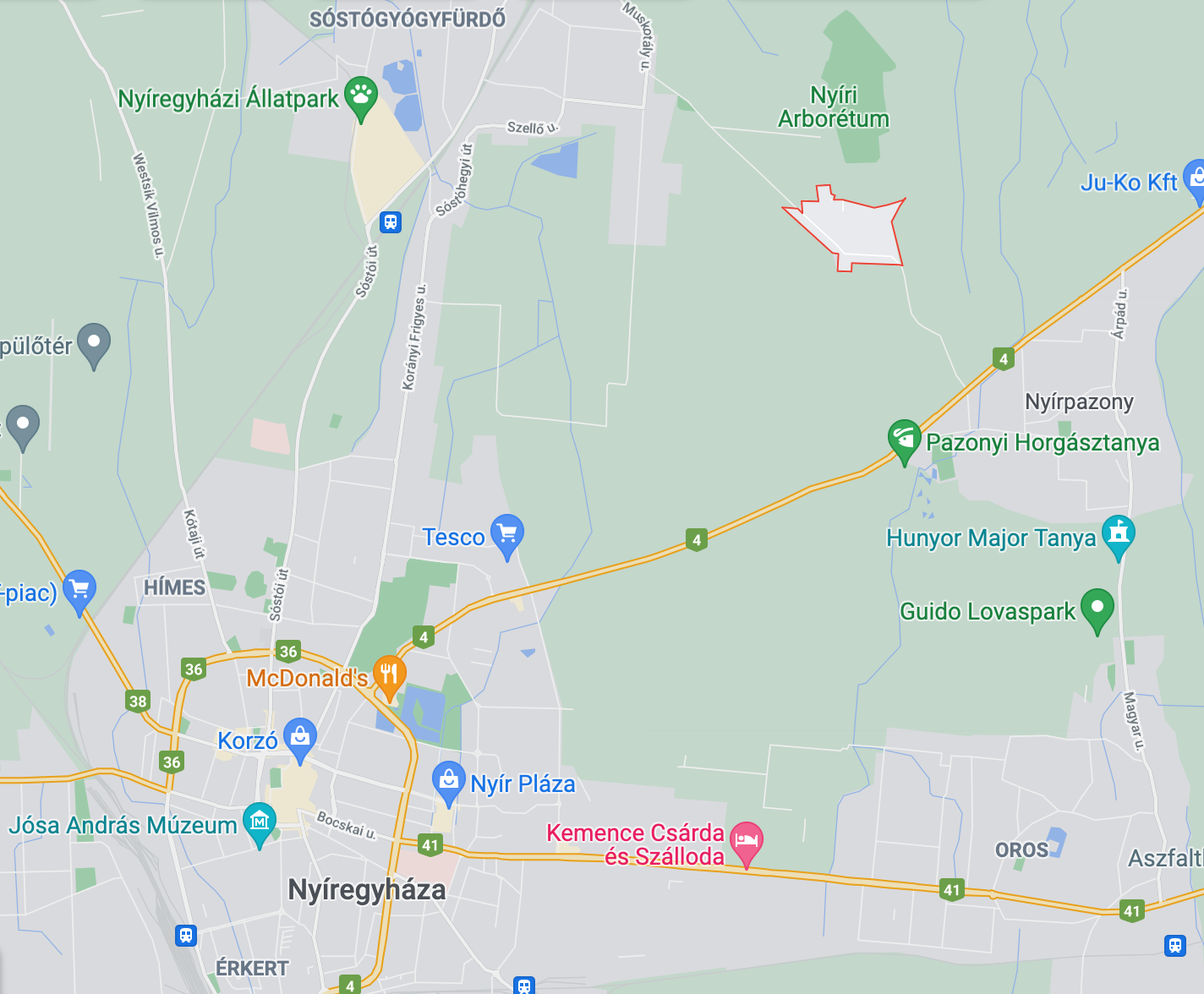

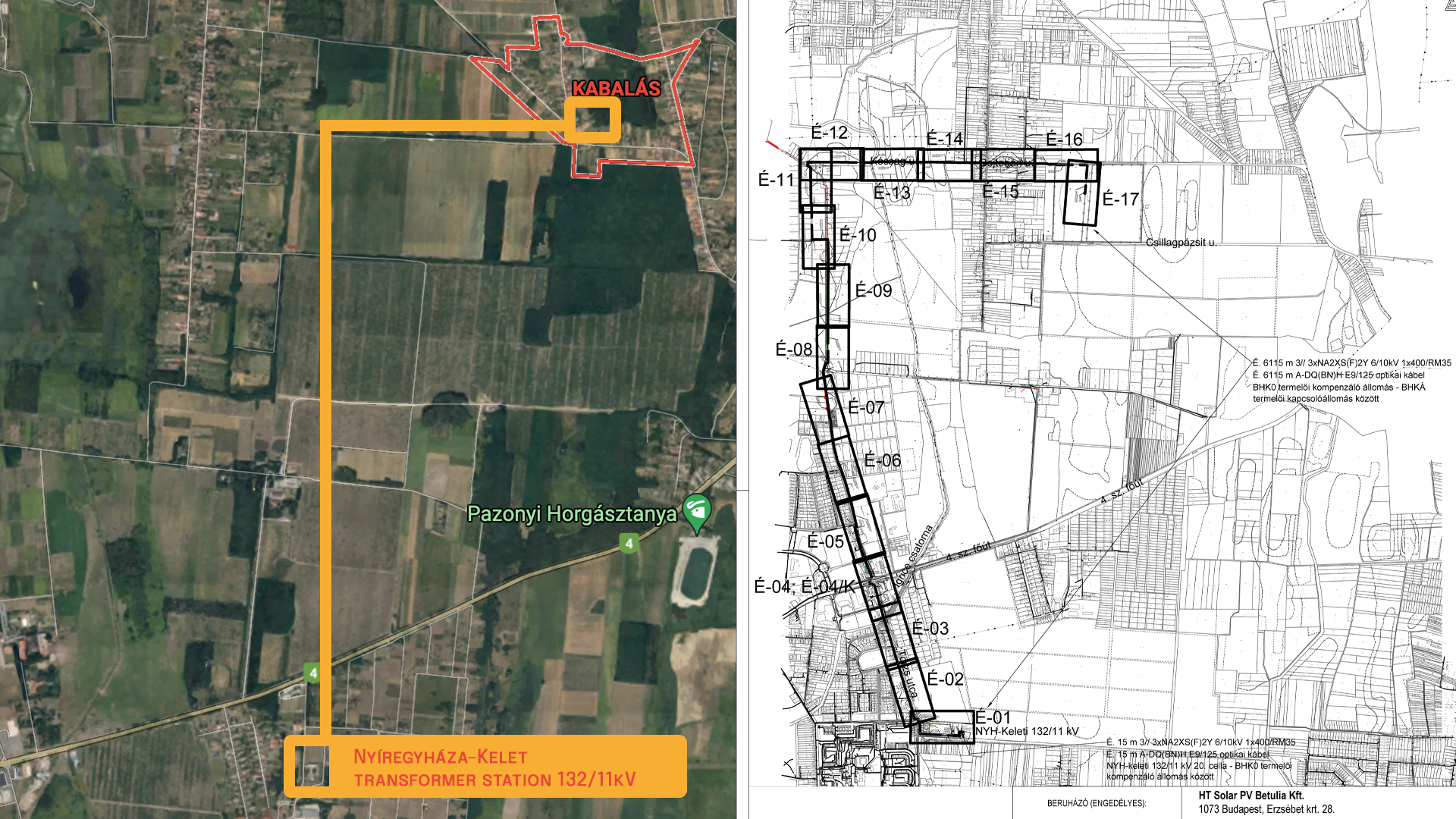

Location

Nyírpazony is a village in Szabolcs-SzatmárBereg county, in the Northern Great Plain region of eastern Hungary. It covers an area of 15.08 km2 and has a population of 3230 people. It is located northeast of Nyíregyháza, next to the main road No. 4, 6 km from the county town. “Kabalás” district belongs to Nyírpazony administratively. It is a part of the settlement located 6 km by road from Nyíregyháza, next to the main road No. 4. It can also be reached on 2 dirt roads from the direction of Nyíregyháza-Sóstóhegy. Due to its proximity to the county seat and the quiet, friendly environment, more and more people are settling in Kabala.

The city-government of the village has decided to handle the project to be a priority investment and both the mayor, Mr. László Dubay and the entire plenum of the village support the implementation at the maximum level.

The Area

The size of the area is 27.2171 hectare, which was just enough to install a ground mounted, grid-connected power plant. An important parameter was the distance of the 11 kV supply point of the network licensee - in this case to the local DSO, E-On/Opus Titasz.

The area does not have any nature reserves bordering. Archaeological findings are not expected in the area and in its immediate vicinity. The measurement data system, the remote monitoring security system and the remote disconnecting unit for connection to the local DSO are able to communicate by using optical cable along the route of the production line.

The investment site has the following road connections:

- The plot area as the site of the power plant is not directly adjacent to a concrete road, but is easily accessible during construction on a short gravel section

- Nearest motorway: number M3, distance: 15 km.

- Nearest main road No. 4, distance 2 km.

It is important for HT Solar PV that the installation of the solar power plant causes the least possible damage to the local ecosystem during the operation of the small power plant and does not change the original terrain conditions. Geological excavation does not take place, the soil related work does not affect surface waters and groundwater. The existing topsoil or other soil layer will not be extracted and / or transported. There was only minimal cultivation during the construction activity. The area was affected by excavation of the underground cable ditches, which were about 2,000 m long and on average 0.2 m wide, and the rammed and gravel-scattered design under the transformer house. The soil layer mined during the excavation of the producer's cable trenches has been restored after construction by re-planning the soil and replacing the crop layer.

When excavating the trenches, the crop layer and the lower soil layer were always separated separately according to the construction instructions.

The Solution

The selection of the designated location was important in several respects, as location is of supreme importance for production. The company has therefore placed tremendous emphasis on choosing an area with a high number of hours of sunshine, above-average sun exposure and above-average microclimate production. Another aspect was the location close to the connection point, so the choice fell on the location on the outskirts of Nyírpazony.

The following aspects dominated the selection of the area:

good sun exposure

no near shadows

proximity to the connection point

the area is consistent, almost square in shape

flat terrain

slight southern slope

Projekt description

The main elements of the investment

Solar panels, also known as solar cells, are the best known and most spectacular parts of solar cell systems. The modules utilise the photo electric phenomenon. By this we mean the conversion of the Sun's radiant energy directly into electricity.

Our preferred solar cell type: Mono-crystalline solar cell, as it can achieve a higher energy density than traditional Polycrystalline cells.

Selected brand: Risen Solar technology and the designated products: TITAN RSM120-8-585M-595M

Risen Energy’s founding in 1986 is a good indication that it has been on the market virtually since thetechnology spread. The high-performance photovoltaic products of the listed manufacturer are at the forefrontworldwide. The company manufactures the cells for the solar panels itself and has a European presence. In2021, their production capacity exceeded 19GW, making them among the top five manufacturers.The company stable, high-quality production at a better price than its competitors. Proven innovations aresoon part of the product portfolio, making their products to be market leaders in key parameters, such ashigher production than their competitors at low irradiation or exceptionally low thermoelectric coefficients.

In the park, we installed the 585Wp, 590 and 595Wp modules of the TITAN series, which were offered by themanufacturer with a performance guarantee far exceeding the industry standards.

Bloomberg TIER1 manufacturer certified

- The company's solar panels have always provided high reliability and excellent performance. The main aspect of product development is quality.

- The company is extremely committed to cleaner energy solutions. Their solar panels and production processes meet the highest environmental standards.

- These solar panels have been sold to more than 70 countries.

- Risen Energy's relevant products have complied with TüV, CE, GS, ROHS, REACH, PAHS and other international certifications and have been leaders in the certification of the ISO14001 environmental management system, the ISO9001 quality management system and the GB / T28000 occupational health and safety management system.

- Risen Energy has more than 45 key business core technologies and has established a nationwide photovoltaic laboratory that is independent and CNAS certified. The laboratory can perform 54 different tests according to EC61215, IEC61730-2 and UL1703.

- The use of white EVA media (back cover) helps to achieve cooler operating conditions of the module, as well as protection against various environmental influences.

- IP68 protection, tempered glass surface, operating range from -40 ° C to +85 ° C

- Frame: anodised aluminium alloy

- Performance: 590-595Wp

- Max DC: 1500V

- Maximum efficiency of 21.2%

The product data sheet is available at this link: Risen Titan RSM120-8

Sungrow Power Supply Co. Ltd is the world's fifth largest manufacturer of inverters. The company was founded in 1997 and employs more than 1,000 people worldwide. Their inverters are used worldwide and have received numerous professional recognitions. Designated model: Sungrow SG 1250-250HX At Intersolar Europe 2019, Sungrow has presented a high-performance 1500V DC string inverter that can be fitted to new systems, and this product is that the company refers as it is currently the most powerful model of their portfolio. The inverters can be paired with double-sided modules, 12 V optimisation modules (MPPT, Max Power Point Tracking) and the so-called with a “flexible block design” of up to 6.3 MW block. According to the company, the model is even suitable for utility projects in mountainous areas. The SG1250/250HX series are able to resist dry desert conditions, but can also be installed in coastal regions, as it is rated IP66 for its physical resistance and C5 for its corrosion resistance. Thanks to its intelligent forced air-cooling technology, it can operate at extremely high temperatures. The system also has a fault diagnosis system and an IV curve scanning function for easier operation and maintenance. The SG250HX can be easily connected to battery storage systems. The system's embedded anti-PID function also reduces module damage, and the enhanced Power Line Communication (PLC) system is designed to be low-cost to install and eliminates the need for additional communication wiring.

Features:

- HIGH PERFORMANCE

- 12 built-in MPPT units, max. efficiency 99%

- Compatible with bifacial module

- Built-in Anti-PID and PID recovery function

- SMART O&M

- Contactless installation and remote firmware update

- Online IV curve scanning and analysis

- Fuse-free design

- Compatible with Al and Cu AC cables

- DC 2 in 1 connection enabled

- Power line communication (PLC)

- low night consumption

The product data sheet is available at this link: Sungrow SG 250HX.

UniVill - SIEMENS three-phase, hermetically sealed oil-insulated power transformers are the industry standard and are made up of state-of-the-art transformer substations.

- Type: 4HB6667-9ZA05

- power: 4000kVA

- Quantity. 5pcs

These advanced devices are mostly installed in a reinforced concrete houses. As a result, they have excellent operating characteristics, economic, safety, environmental and architectural parameters. These transformer stations are the safest because all the technologically relevant parts are located inside the building. Its operational safety is thus outstanding.

In the event of an accident, this must not cause damage to property or endanger the health of the people around it. In addition to safety, these types of stations are characterised by features such as fast construction, low operating costs, minimal maintenance and environmentally friendly operation.

Technical description of the concrete housing transformer station

- The raw material of the KSW40-30-4000 kVA transformer substation is concrete, which meets the electrical, thermal and mechanical requirements according to the standard MSZ EN 62271-202: 2014. The station is monolithically cast in one piece and built without gaps. The compressive strength of concrete complies with class C30 / 37. The station consists of three compartments, a medium voltage space, a transformer space, and a low voltage space.

The part of the monolithic reinforced concrete body sunk into the ground is suitable for catching oil leaking from the transformer in the event of a transformer failure. Water-tight bushings are provided in the appropriate parts of the base for the bushing of medium and low voltage and control cables.

The doors are made of 2 mm thick galvanised sheet steel and are coated with powder coating technology. The doors of the station meet the criteria for arc and pressure resistance. On doors with ventilation slats, there is a grille made of stainless steel behind the slats to prevent the intrusion of beetles. The doors have an opening angle of 110 ° and the door catches engage automatically when the maximum opening angle is reached. The door catches are positioned so as not to interfere with work on medium and low voltage equipment. The locks have profiled half-cylinder lock inserts and a rain cover.

The roof is designed as a separate building element, which can be replaced or repaired. In case of replacement, the station can be removed from the concrete body on site. The roof is attached to the station body at four points. There are two anchor points in the low voltage space and two anchor points in the medium voltage space.

Electrical parameters of the switchgear:

- Rated voltage: 24 kV

- Rated current: 630A

- Rated frequency: 50 Hz

- Industrial frequency test voltage: 50 kV / 1 minute

- Impact test voltage: 125 kV

- Thermal limit current: 16 kA

- Thermal time limit: 1 s

- Arc resistance class: AFL-16kA / 1s

- Operating voltage: 24V DC

Scheduled implementation

Planning processes began in May 2020. The submission and approval of the Accession Plan was planned to take 6 months, and the attainment of the building permit took 3 months. The design and permitting phase have been followed by construction work, which began in September 2021 and completed in end of June 2022. The final occupancy permit was issued on October 15, 2022.

11kV cable connection between the solar plant and the local DSO Substation.

(Opus Titász: Nyíregyháza-Kelet 132/11kV busbar/cubicle). Total 11kV cable path length: 6132 m

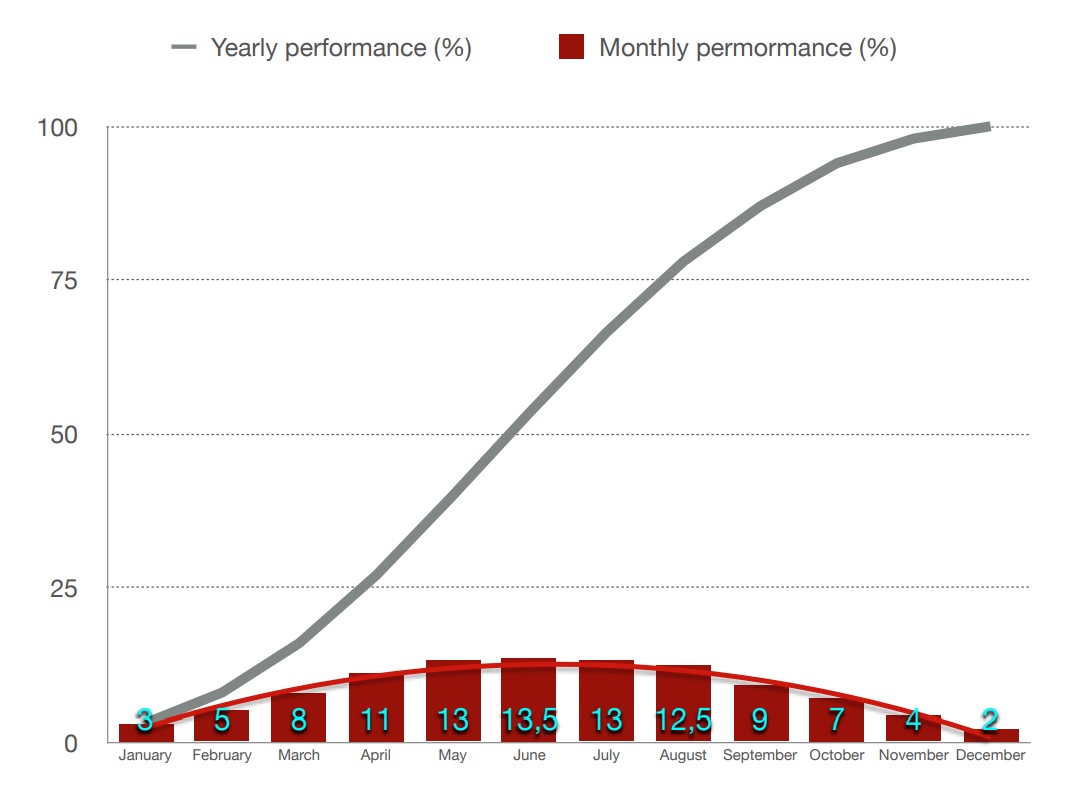

Yield calculations, estimations, Power Ratio prediction

Brief business plan

Planned revenue growth and return on investment expected from the investment Revenue planning:

- annual global radiation on the plane of the modules: 1,348 kWh / m2

- rated DC power: 23,672 kWp

- power plant efficiency: 83.1%

- 10-year average amount of electricity generated: 29.36 GWh

- system self-consumption: 0.096 GWh

- the amount of electricity produced for the first full year (2023): 30.127 GWh

- producer cable loss: 400,000kWh or 0.4GWh

- amount of electricity available for sale: 30.127 GWh

Media (08/04/2022 status)

HT SOLAR PV BETULIA KFT.

- penzugy@htsolar.hu

- +36 30 257 4777

1073 Budapest, Erzsébet körút 28.,

Budapest Hungary